Company

Welcome to Sapphire Technologie! We are a team of full service providers of world-class label printing equipments and supplies. We provide our value added customers with labeling, tagging and barcoding solutions, products including an extensive selection of thermal label printers, thermal labels , tags, ribbons, and accessories such as

label applicators and dispensers. We take the time to learn about our customers’ specific needs, then provide a comprehensive solutions, combining the right labeling equipments with assets and inventory management softwares and hardwares including barcode scanners and data collection units / mobile computer or terminals.

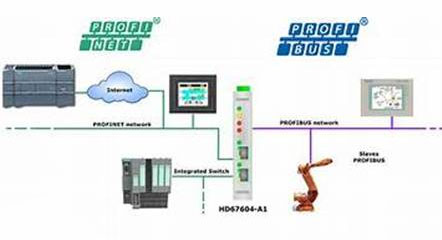

PROFIBUS is a serial classic field bus and PROFINET is an industrial Ethernet protocol. PROFINET and PROFIBUS are both IEC standards Created by the same organization. PROFINE and PROFIBUS INTERNATIONAL PROFINET AND PROFIBUS share same similarities, because of their common source.

Services

Our Labeling Services

Products

we are barcode scanner dealers. POCKET BARCODE SCANNER | DATALOGIC RIDA DBT 6400 2D BLUE TOOTH | Pocket Scanner Zebra CS4070, A barcode scanner is also known as a barcode reader is an electronic device OR equipment that decodes and automatically captures data’s coded in barcodes. It consists of the following technological components, which accurately work together to capture data’s contained in a printed barcode.

The Zebra ZD410 is an excellent barcode printer for price-sensitive buyers. It's compact, reliable, and offers high-quality printing. Ideal for small to medium businesses, it supports various label sizes and integrates easily with existing systems, providing great value without compromising performance..

we are barcode printer custmer care and service centre . if you need regading barcode printer service please call us ,provide best sales and service support . we also deal in software service supportID card printers are almost the size of Desk top Ink jet printers or Narrow desk top computer CPU’s. These card printers are only used for printing PVC ID cards only. However the printing technology used in these printer are different when compared to desk top inkjet printers. While ink jet printer has a paper tray and ink cartridges, an ID card printer has an card input slot and card output slot/tray as well as the ink carried on ribbon.

“ALL FOR ONE AND ONE FOR ALL” One Stop Shop Business Management Software. CRM software in delhi, Inventory Management Software in delhi, ERP management software in delhi, Vehicle Tracking management software in delhi, Tracking & Tracing management software in delhi, Patient Tracking software in delhi, Pathological Applications software, Patient Tracking Record Room Management software in delhi, Library Automations management software in delhi, Student Tracking software, Asset Management software, Work Force Management software in delhi, Supply Chain management software in delhi & logistics Scheduling Production management software and Manufacturing management Software in delhi. We provide all under One Umbrella and All in one place ie; Sapphire Technologie

Chrome paper barcode labels are essential for various industries due to their durability and high-quality print capabilities. These labels are made from chrome-coated paper, which offers a smooth and glossy surface ideal for sharp barcode printing. The chrome coating enhances the label's resistance to moisture, chemicals, and abrasion, making them suitable for both indoor and outdoor use. The primary advantage of chrome paper barcode labels is their superior print clarity. This ensures that barcodes are easily scannable, reducing errors in data collection and improving efficiency in inventory management, logistics, and retail environments. The labels are compatible with various printing technologies, including thermal transfer and laser printers, allowing for versatile application. Chrome paper barcode labels are also customizable. They can be produced in different sizes, shapes, and designs to meet specific requirements. This customization is crucial for branding, as companies can incorporate logos, product information, and other relevant details alongside the barcode. In summary, chrome paper barcode labels offer a combination of durability, high print quality, and versatility. These features make them a reliable choice for businesses looking to enhance their product tracking, inventory management, and overall operational efficiency

adhesive labels used in direct thermal printing technology. They are coated with a heat-sensitive material that reacts to the heat generated by a direct thermal printer. The printer applies heat directly to the label, causing a chemical reaction that creates a visible image or barcode without the need for ink or ribbons. Direct thermal labels are commonly used for shipping labels, barcode labels, name badges, receipts, and other applications that require temporary labeling. They are cost-effective, easy to use, and offer good print quality. However, direct thermal labels are sensitive to heat and sunlight, which may cause fading or discoloration over time.

A polyester paper label is a specialized adhesive label that combines the durability of polyester paper label with the printability of paper. It is made from a polyester film that is coated with a paper-like surface, offering the best of both materials. The polyester paper label layer provides excellent resistance to tearing, moisture, and chemicals, making it suitable for applications in challenging environments. polyester paper label -like coating allows for high-resolution printing using inkjet or laser printers. Polyester paper labels are commonly used for product labels, asset tracking, identification labels, and outdoor signage. They offer a balance between durability and print quality, making them a versatile choice for various labeling needs.

A transparent label is a specialized adhesive label made from a clear or translucent material, typically a transparent film or acetate. These labels are designed to be applied to surfaces while allowing the underlying surface to be visible. Transparent labels are often used for packaging, product labeling, branding, or decorative purposes where maintaining the visibility of the surface or showcasing the contents is desired. They offer a professional and sleek appearance, blending seamlessly with the background and giving a "no-label" look. Transparent labels can be printed with text, images, or barcodes using inkjet or laser printers, providing versatility and customization options for various labeling needs.

A vinyl label is a type of adhesive label made from vinyl material. Vinyl labels are known for their durability, flexibility, and resistance to moisture, chemicals, and UV exposure. They are commonly used for outdoor applications or in environments that require labels to withstand harsh conditions. Vinyl labels adhere well to various surfaces, including plastic, metal, glass, and even curved or uneven surfaces. They can be printed with vibrant colors and high-resolution graphics using inkjet or thermal transfer printing methods. Vinyl labels are widely used for product labeling, equipment identification, safety signs, vehicle decals, and durable outdoor signage, providing long-lasting and visually appealing labeling solutions.

Premium Paper Label Manufacturer – Serving Delhi, Haryana, Rajasthan, Punjab & UP Looking for a reliable paper label manufacturer in North India? Your search ends here! We are a trusted name in the industry, offering top-quality paper labels customized to your business needs. Whether you're in Delhi, Haryana, Rajasthan, Punjab, or Uttar Pradesh, we ensure timely delivery, competitive pricing, and unmatched quality. Our manufacturing facilities are strategically located to serve major industrial zones. We proudly cater to clients in Delhi, Rohtak, Narela, Sonipat, Bawana, Gurgaon, Gurugram, Faridabad, Bahadurgarh, and Sahibabad—ensuring quick turnaround and reliable support across the NCR region. In Rajasthan, we are a go-to choice for businesses in Bhiwadi, Bawal, Rewari, Alwar, and Neemrana. Our specialized production processes allow us to handle both large-scale orders and custom, niche requirements. From pharmaceutical to food and beverage, FMCG to industrial packaging, our paper labels meet high standards of durability and clarity. With our cutting-edge printing technology and eco-friendly materials, we help you showcase your brand with precision. We also serve regions in Punjab, Muradabad, Rudrapur, and Dehradun, extending our high-quality labeling solutions to more corners of North India. Whether you're in Noida, Greater Noida, or other parts of Uttar Pradesh, we’re just a call away. Let us help your business make a lasting impression. Choose a paper label partner that delivers quality, consistency, and cost-effectiveness. Contact us today for custom quotes and samples! .

professional Client.